Lubricity Evaluation Monitor

Brand:

OFI Testing Equipment, Inc.

Product Code:

113-00

Availability:

Call for availability

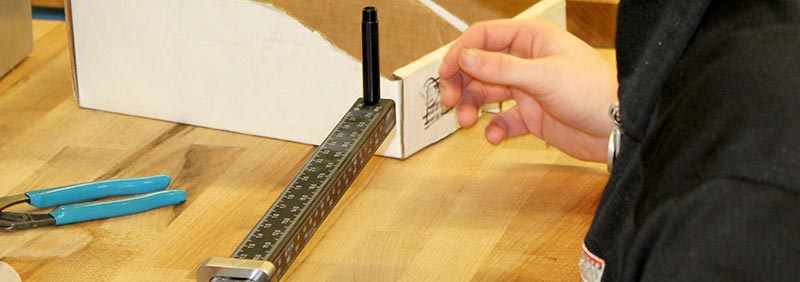

The Lubricity Evaluation Monitor (LEM) is a laboratory device designed to evaluate lubricants by direct comparison. It determines the coefficient of friction between an interchangeable wellbore sample (casing, formation, sandstone, etc.) pressed against a rotating steel bob while immersed in a circulating cup of test fluid.

Features

- Pneumatic ram applies side load pushing the bob against the sample

- Periodic refresh of test fluid by pulling bob away from sample at definable intervals

- Clamp allows samples of casing, formation, sandstone, etc. to be tested in the same fixture

- Computerized data acquisition and control

- Optional Heat Cup allows heating the fluid up to 180°F (82.2°C)

- Software

- Operator inputs rotational speed, side load, and refresh period

- Test archive provides access to historical data

- Graphs rotational speed (RPM), torque (in-lb), side load (lb), and coefficient of friction with respect to time

Specifications

- Sample cup capacity: 350 mL

- Range of Mud Weights: 0.83 - 18.0 lbs

- Torque Transducer Maximum Range: 100 lbf-in

- Torque Resolution: +/- 0.1% of full scale combined

- Maximum Side Load: 60 lbf

- Maximum Rotational Speed: 200 RPM

- Maximum Temperature (with optional Heat Cup): 180°F (82.2°C)

- Speed of Circulating Pump: 20 - 500 RPM

- Calibration: Coefficient of Friction of Water = .32 - .36

- Test Cell Material: Acrylic

- Bob Material: 4140 Steel - Rockwell Hardness of 37

Requirements

- Electrical Supply: 220 Volts

- Air Supply: 60 - 100 PSI

Part Number

- #113-00: Lubricity Evaluation Monitor

- #113-00-101: Optional Heat Cup