Newsroom

Pressurized Viscometers for Fracturing Fluids

Fracturing fluids are viscous mixtures of water and additives that are pumped at high pressures into an underground oil or natural gas formation. They are designed to fracture the formation and carry proppant into the newly formed cracks. Once the proppant is placed, the fracturing fluid flows back to the surface for disposal by the service company. Proppant left inside the fractures provides liquid hydrocarbons an easy path to flow out of the formation and up to the surface.

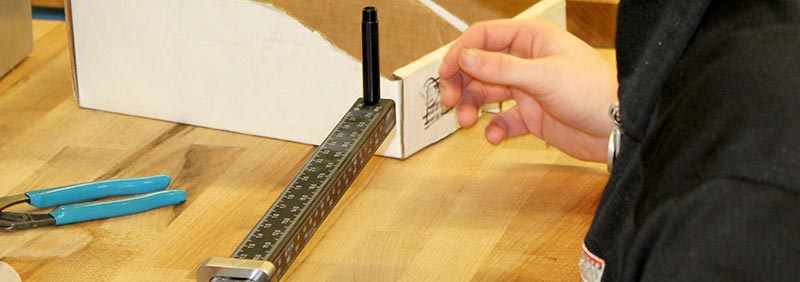

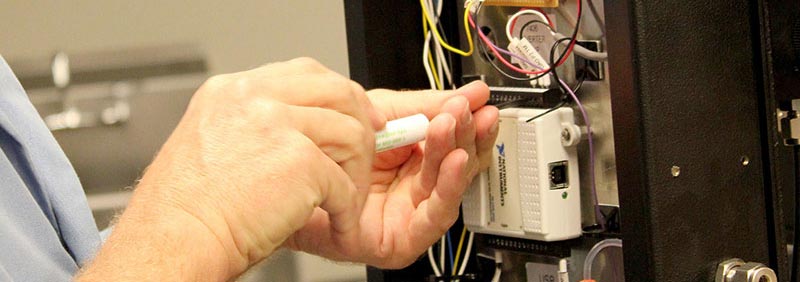

The fracturing fluid is the key component to the stimulation process. It needs to have enough viscosity to carry the proppant, but it must also "break" and lose viscosity so that it will flow back to the surface without blocking the production of hydrocarbons from the formation. The Pressurized Viscometer is the essential tool service companies use to finalize the fracturing fluid design. A Pressurized Viscometer applies temperature and pressure to a fracturing fluid in order to determine the stability response of the fluid at downhole conditions. The viscometer determines the fluid’s viscosity by measuring its response to different rotational shear rates imparted by a rotor and bob combination (also known as a couette configuration). Engineers then use the apparent viscosity of the fluid to optimize the design and make sure it is capable of effectively delivering the proppant into the hydrocarbon bearing formation.